An introduction to the electric heating mixing tank for the production of guar gum in the food factory

Guar gum is made from the leguminous plant guar, a natural galactomannan that is a commonly used food additive in many processed foods. Guar gum is used to thicken and bind food. It has high soluble fiber content and low calorie content. It can be dissolved in cold or hot water, and forms a jelly-like substance when it encounters water, achieving the effect of rapid thickening. Because of its unique properties, it is widely used in food, cosmetics, pharmaceuticals, textiles and other industries.

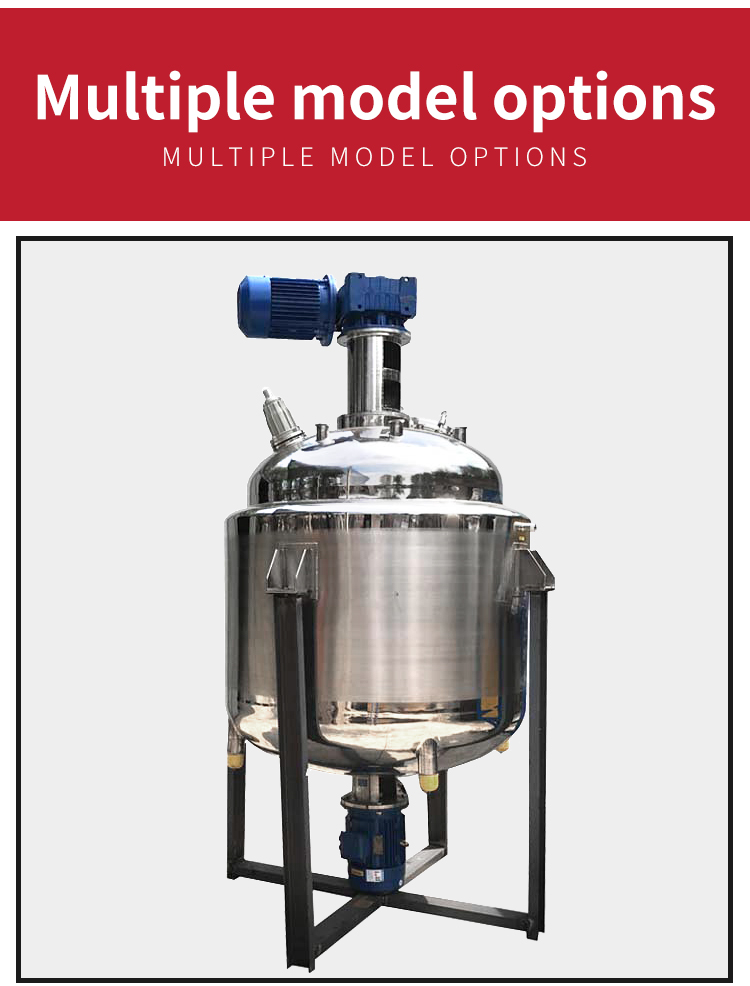

Recently, a customer from a food factory came to our company to inquire about the use of mixing tank equipment for guar gum thickener. After understanding the production requirements and the characteristics of the materials from the customer, our company's technical staff has formulated the equipment plan according to the customer's requirements. Since the density of guar gum is 1.492g/cm3, it can be completely dissolved in cold water and hot water, so during the dissolution process, the electric heating thermal insulation stirring tank can play its function. The tank body is made of 304 stainless steel, including each joint. Accessories and screws, and the production process of the tank are also mirror-polished inside and out, which not only has a beautiful appearance but also ensures the sanitation of the tank, so that the material will not produce hygienic dead corners during the mixing process, and it is easy to clean. The mixer is made of hollow thick-walled tube or solid tube according to the process requirements to ensure that there will be no bending phenomenon during long-term use. The mixer base has built-in stainless steel bearings and a protective cover to prevent dust and dirty oil from falling into the tank. Contaminate the product in the tank. The agitator motor can be configured with domestic and foreign brands, with low noise and stable power, and can support continuous work. The shell of the distribution box can be made of 304 stainless steel, with a built-in intelligent temperature controller. Customers can adjust and control according to their actual temperature requirements.

Huazhiyi Technology's electric heating mixing tank can be custom designed and produced in terms of structural design and specifications according to the customer's process and use requirements. The customized stainless steel storage tank is more user-friendly in operation and more suitable for customer production needs. . The production of our company's tank equipment is strictly in accordance with the requirements of national food-grade equipment in terms of materials and workmanship. Every detail is carefully produced, Huazhiyi Technology is responsible for the product, responsible for the customer, and responsible for itself!

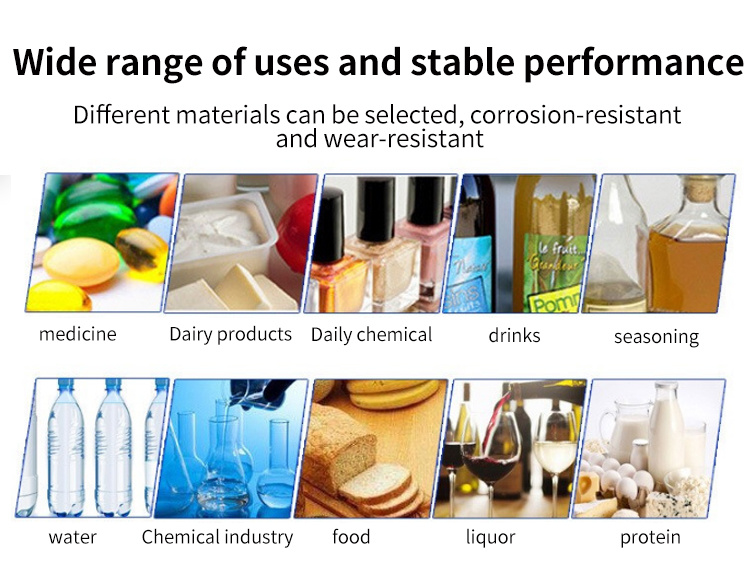

Electric heating stirring tank: Seiko Huazhiyi brand electric heating stirring tank (also known as reaction kettle, hot and cold tank, batching tank, mixing tank, water phase tank, dissolving tank, etc.), widely used in chemical industry, paint, medicine , pigments, resins, food, building materials, agriculture, scientific research and other industries, the selection of materials is excellent, the standard is made of SUS304 stainless steel for food; other 316L\340 and so on can be selected; this equipment is tailored according to the actual needs of customers, For example: vacuuming, heating, cooling, thermal insulation devices, etc. to meet different process and production needs, electric heating stirring tank, heating methods are: heat conduction oil heat conduction, hot water circulating heating, coil steam heating; the structure of the equipment Reasonable design, advanced technology, durable, large heating area, uniform heating, adjustable heating temperature, for the electric heating type mixing tank, the company has strict requirements on heating and sealing, and fine workmanship.

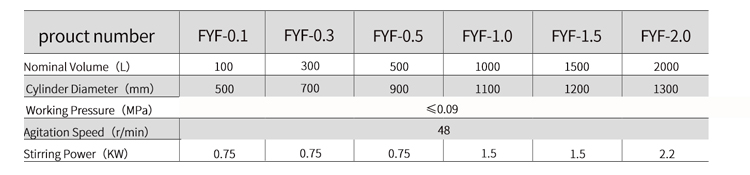

Main technology and structural performance of reaction kettle/electric heating chemical stirring tank: The volume is matched according to the actual needs of customers, such as: 50L, 100L, 200L, 300L, 500L, 600L, 800L\1000L, 2000L~5000L. The heating and stirring tank produced by our company has an optional heating method: generally, an electric heating rod is used to extend into the jacket, and the heating is even and there is no cold zone. Heat transfer oil or water can be injected into the jacket as the heating medium to generate heat energy to heat the materials in the tank. Steam heating can also be used; material heating temperature can be adjusted: ≤ 200 °C (if the temperature is high, it is recommended to add an additional layer of thermal insulation layer); material heating time: 30min ~ 120min (depending on the process needs).

Due to the variety of models, materials and specifications of the manufacturer's products, the prices on this website are for reference.

The specific actual price needs to be determined after the customer communicates with the relevant personnel of my company.

The actual product price is determined by the actual materials and specifications used.