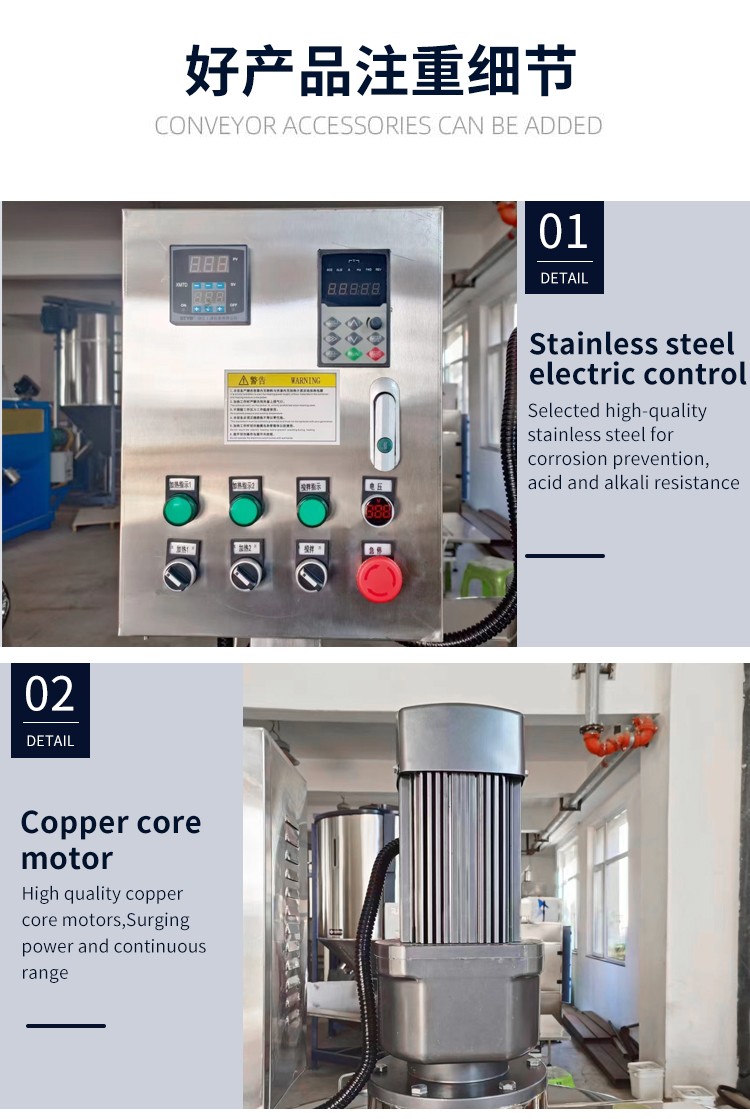

Today we introduce a corrosion-resistant stainless steel mixing tank

Liquid mixing tanks are mainly used in industries such as food, daily chemical, and petroleum, such as coatings, pigments, laundry detergent, detergent, shower gel, glue, resin, etc. They are containers for completing hydrolysis, neutralization, crystallization, evaporation, mixing, and other process processes. They can also be equipped with heating devices, insulation devices, and cooling devices according to customer process requirements.

Introduction to Liquid Mixing Tank:

1. Equipment material: SUS304 stainless steel, SUS316L stainless steel, etc.

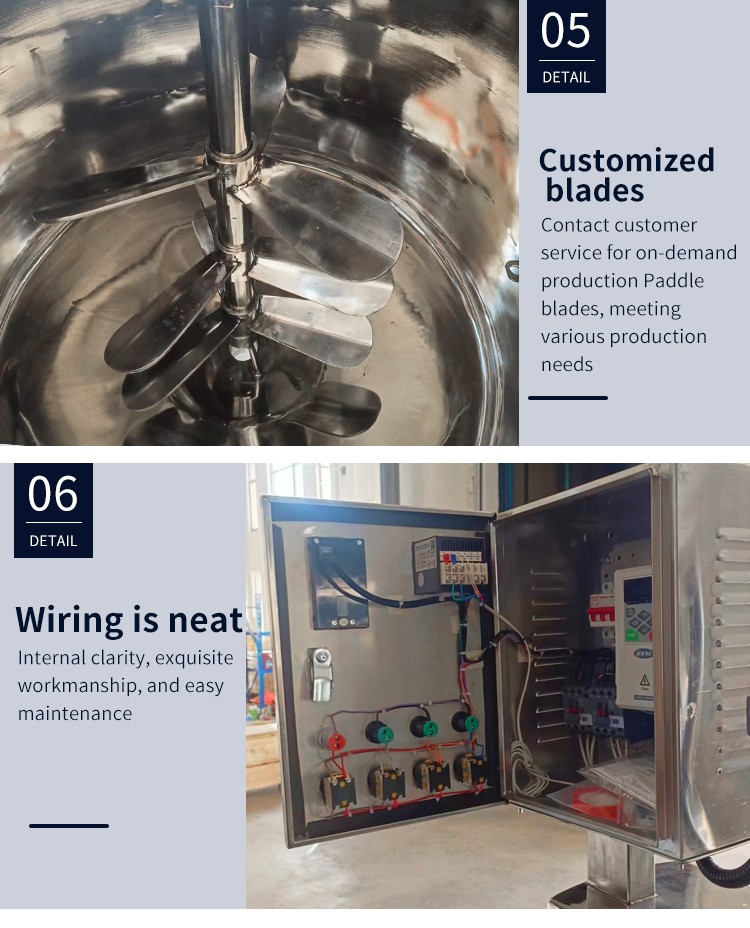

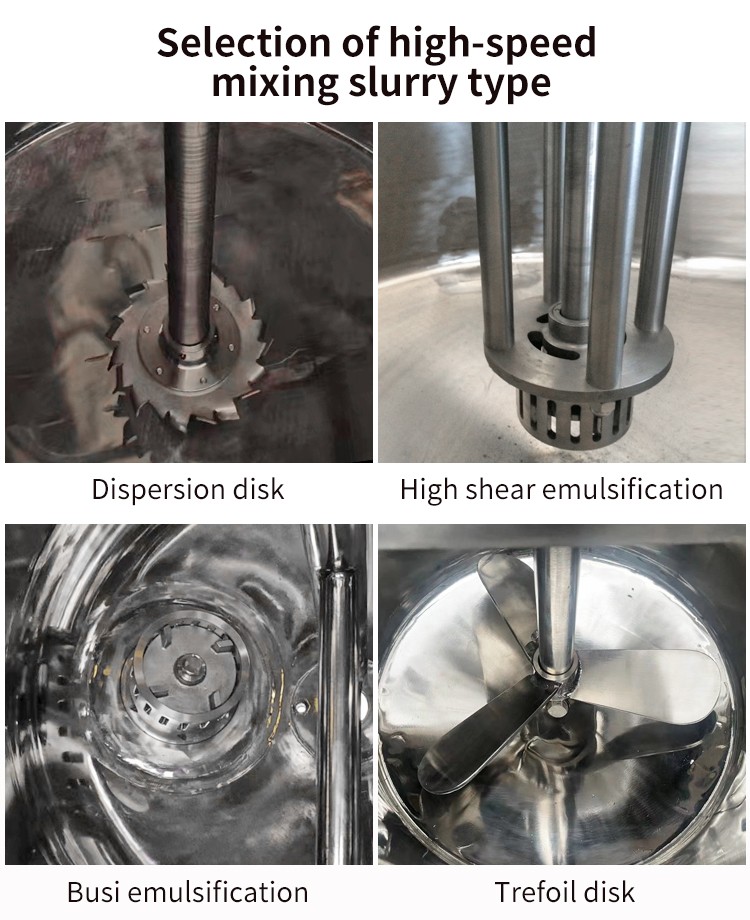

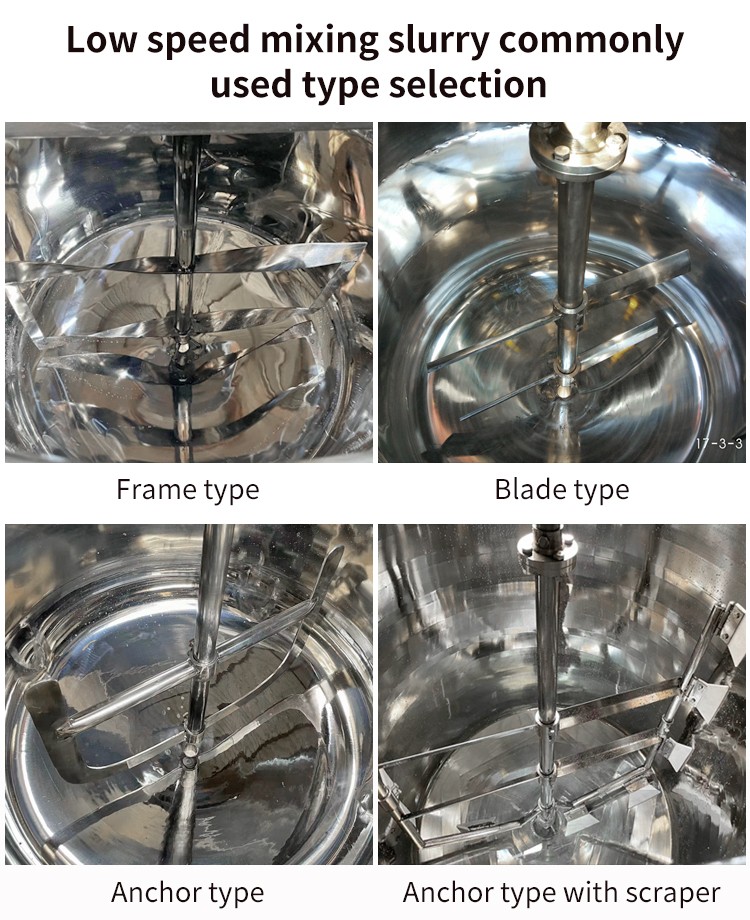

2. Mixing forms: paddle type, anchor paddle type, frame type, spiral belt type, turbine type, dispersed disc type, combination type, etc.

3. Heating method: electric heating, steam heating, water bath heating.

4. Heat transfer medium: heat transfer oil, steam, hot water, electric heating.

5. Heat transfer structure: jacket type, outer coil tube type, inner coil tube type.

6. Equipment structure: upper and lower flat bottoms, upper and lower slants, upper and lower cones, upper and lower heads, etc.

7. The mixing tank can be customized to process 100L-5000L according to customer process requirements.